Applying Systems Thinking to Warehouse Execution Software

This blog is part two in a series read part one: Optimizing Automated Distribution Centers: The Power of Systems Thinking.

As automation adoption increases in warehouses, many companies end up with “islands of automation.” For example: Automated picking systems might operate independently from automated storage and retrieval systems (ASRS). While these individual systems can enhance certain operations, the failure of one island of automation can ripple across the system, slowing the overall efficiency of warehouse operations.

When these issues occur implementing a warehouse execution software (WES), combined with systems thinking, creates a unified approach. The WES acts as the brain of the distribution center, coordinating the various automated systems to ensure they work together smoothly.

By applying systems thinking, the WES can optimize the interaction between different islands of automation, transforming them into a well-integrated, high-performance system. Here are key ways a WES, through systems thinking, can help optimize a fully automated warehouse:

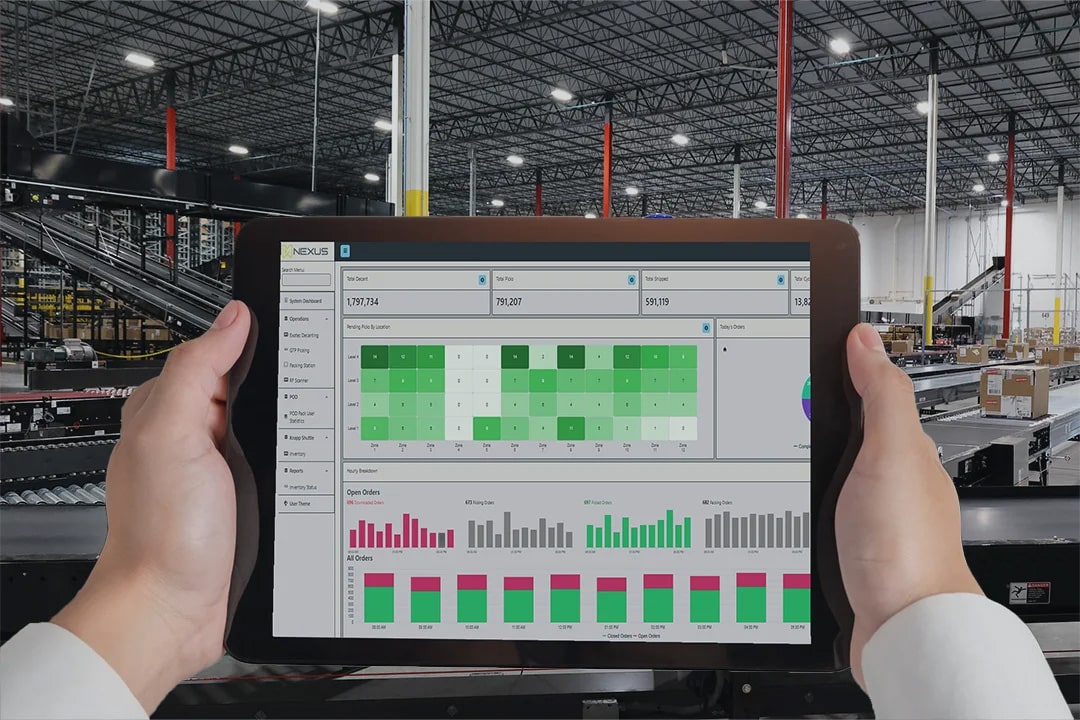

1.Real-time Monitoring and Coordination

The WES provides real-time data on all aspects of warehouse operations. By constantly monitoring each system—whether it’s picking, sorting, or packaging—a WES can detect bottlenecks and scheduling conflicts. This dynamic coordination prevents individual systems from being overburdened or underutilized.

2.End-to-End Process Visibility

A WES offers holistic visibility across the entire system, from order receipt to product shipment. By integrating data from all automation subsystems (robotics, conveyors, ASRS, etc.) and software (WMS), a WES can ensure that materials are routed efficiently and with minimal delay. This end-to-end visibility also allows managers to make data-driven decisions about operational adjustments, helping them see the entire flow of goods and respond quickly to changes or disruptions in the system.

3.Optimizing Workflow and Reducing Delays

The WES analyzes the performance of the entire warehouse—not just individual machines or automation components. It can help optimize the sequence in which orders are processed, allocate resources (AMRs, robots) to high-priority tasks, and dynamically adjust workflows to prevent congestion in one part of the system.

4.Integrating Manual and Automated Systems

In most warehouses, a mix of manual and automated processes exists. The process of systems thinking allows the WES to seamlessly integrate human workers with automated systems. For example, while robots might handle repetitive tasks like picking or sorting, workers may still be needed for more complex tasks like quality control, packaging, or last-mile delivery. A WES ensures that automated and manual systems work in tandem, optimizing the flow of work and improving productivity.

5.Improved Resource Allocation

A system-thinking approach ensures that resources, whether labor, robots, or machines, are allocated where they will have the most impact. By analyzing how each part of the system performs in relation to others, a WES can adjust resources dynamically. This adaptive allocation maximizes throughput and minimizes idle time.

Unlocking the Full Potential of Automation with Systems Thinking

As warehouse automation continues to advance, adopting a systems thinking approach in your strategy has become essential for companies aiming to optimize their automated distribution centers. This mindset is crucial for staying competitive in the fast-paced realm of logistics and supply chain management.

About the Author

David Scott is a Vice President of Software Engineering with over 30 years of experience leading innovative software organizations in the manufacturing and supply chain industries. David is passionate about helping customers achieve streamlined operations, enhance productivity, and drive business transformation.